Ignition sequence 1 – 3 – 4 – 2

With the Cleon engine, the cylinders are numbered from the rear (clutch side) to the front. This corresponds to the German industry standard (DIN 73021).

Knowing this fact can have very practical consequences if you e. g. remove the distributor cap and then want to put the plugs back on when mounting,

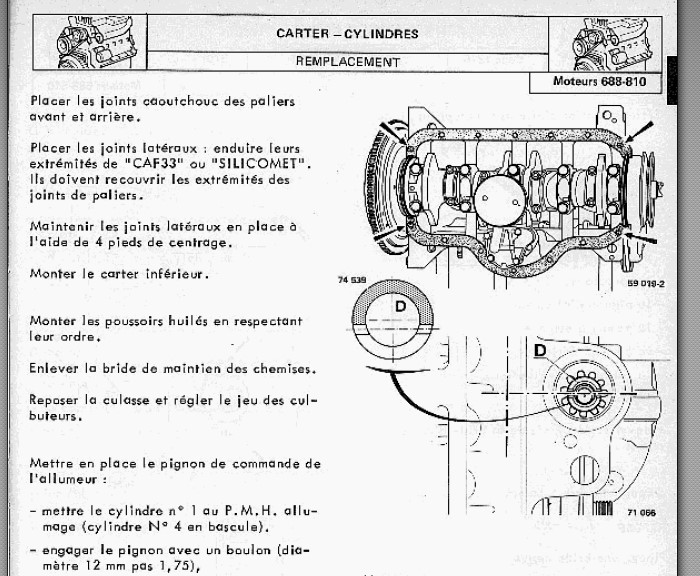

Or if the pinion of the distributor drive is to be assemplied,

Or if at the Estafette meeting someone has ignition problems and then the ignition sequence is discussed.

The ignition sequence 1 – 3 – 4 – 2 always remains the same, no matter if the rear or front cylinder is your personal number one 🙂

Electronic Ignition

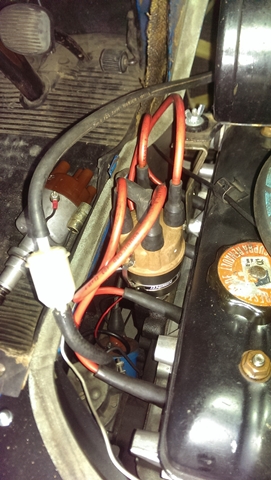

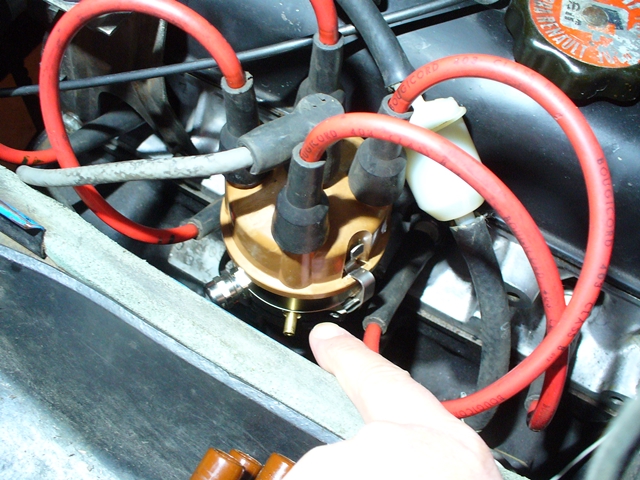

We equipped Couchette and Louise with electronic ignition from 123ignition. We made troughout positive experiences.

For both, we chose the version with vacuum control

Couchette (1970) still has the single-circuit braking system w/o master-vac connection , so it was necessary to build a corresponding vacuum connection (the distributor in the picture is from the 1978 VBZ bus).

For Louise it was possible to use the existing vacuum connection -> see Louise-Engine

In addition to the ignition distributor, we also installed the recommended Bosch ignition coil (>1 Ohm)

The mounting was easy – just replace and stick on the vacuum tube, for the ajustment cylinder number 1 set to TDC and turn the distributor until the LED is switched on

Then starting engine and finetune with stroboscope lamp (or by ear as i did 🙂 )

https://www.123ignitionshop.com

https://passion-estafette.ch/wp-content/uploads/media/files/123ignition_1.pdf

Exhaust regulations

In switzerland Oldtimer until 1975 are released from exhaust regulations .

Vehicules w/o On-Board-Diagnosis-System (OBD from 1976 and younger have to pass an exhaust examination every year resp. vehicules with catalytic convertor every 2 years (Vignette).

Couchette und Louise are both released from exhaust regulations

So it is not necessary to improve the exhaust, however it is more comfortable not to be the stinker for the other road users

Lamda Regulation

With a Lambda regulation it is possible to reduce the emission values on carburator engines . The lambda oxigene sensor, set directly in the manifold, measures the left over oxigene. the regulator opens an closes an air intake valve (pulse valve, or step motor valve) which directs air from air filter over a pipe into the ditributor (directly after the crburator ). This works as long as the carburators adjustment is slightly fat. this must be ensured over all operating conditions

AMM-L1

For many german and some italien and french cars complet sets with oxygene sensor, regulator, air valve and even prepared exhaust pipe systems with catalytic convertor are available, but not for the Renault Cleon engines – at least i dind’t find any .

After some research in WWW i found the AMM-L1 regulator – it was invented for the “big bore” Harley’s – but can be used for car engines as well

http://www.altmann.haan.de/L1/default.htm

The lambda oxigene sensor and the AMM-L1 can be used for the principal carburator setup .

The Base setup is done at 1000 rpm

If carburator is top adjusted, then green LED is permanently blinking

If LED is for a longer period ON then engine operates too fat.

If LED is a longer time OFF, then engine operates too lean .

This way one get very fast a feedback during the test ride and can adjust acordingly.

For this you simply re-adjust the mixture adjusting screw.

When the setup can be well adjust for the lower, – but not fot the higher turns then the main nozzle is incorrect and must be exchanged.

A first try with Couchette

The Lambda sensor reaches operating temperature after about 1 minute. First, I saw that the carburetor was set too fat! During the test drive I quickly found an good average. So far so good – but now if the engine is hot and on idle speed, the engine starts to run rhythmically in 2-3 seconds tact– to prevent this, there is an additional connection at the regulator for engine idle operation . The kit includes a micro switch which has to be mounted in an appropriate place (e. g. at the throttle lever) . This way regulator is interupt when engine is on idle speed

But I decided to mount a manual toggle switch – which i use when waiting at traffic lights or at stop-and-go traffic.

Catalytic Convertor

Theoretically now a catalytic convertor – which has a suitable length and size (flow trough) – can be mounted directly behind the oxygene sensor. This way it should be possible to reach EUR1