Rule of thumb

From my motorcycle days I know folowing rule of thumb 1/4, 2/4, 1/4

-> first quarter is determined mainly by the idle mixing control screw (& idle nozzle)

-> the second and third quarter is significantly controlled by the nozzle needle.

-> the last quarter then significantly from the main nozzle

For carburetors without jet needle one could now derive the following rule of thumb – without warranty 😇 :

-> first quarter is largely determined by the idle mixture control screw (& idle jet or pilot jet)

-> the second and third quarter is determined by the main jet

-> the last quarter is mainly determined by the air correction jet (reduces the effect of the main jet)

See also the article Carburetor Jets about carburetor jettig in Rob and Dave’s Aircooled Volkswagen Web Pages

At ruddies-berlin. de there is a keyword directory

What the heck is Econostat 😀 ? ( mixture enrichment )

According to Rob and Dave, the effect of the main jet is already noticeable with a change of one step, while the air correction jet is only noticeable with 3-4 steps – which I can confirm (the main jets are offered in steps of 2.5 = 0.025mm)

The effect of idle mixture control screw also depends on the jet – here is a very informative Youtube contribution:

Carburettor jetting 1 , idling – idling jet, main jet and air correction jet should be selected so that the position of the idling mixture regulating screw is about 2.5 – 3 revolutions.

With the Lambda Regulation I noticed that the my carburators do not held a balanced mixture over the whole speed range ,

With the 32 DIS from my Couchette (main jet 107. 5), if well adjusted in the lower area, the mixture was a bit too lean in the upper speed range (air correction jet 160).

Unlike the 32 DIR (Weber) – here, if set well in the lower range, the mixture was much too fat in the upper range of rotation (air correction jet 100).

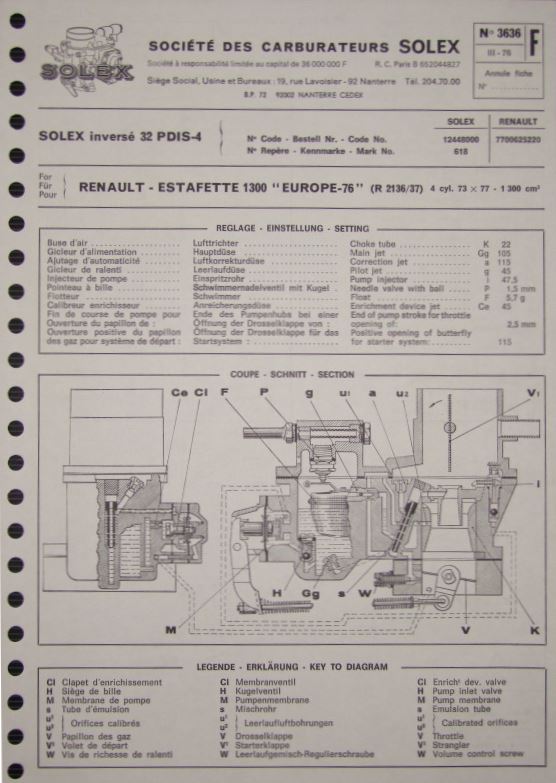

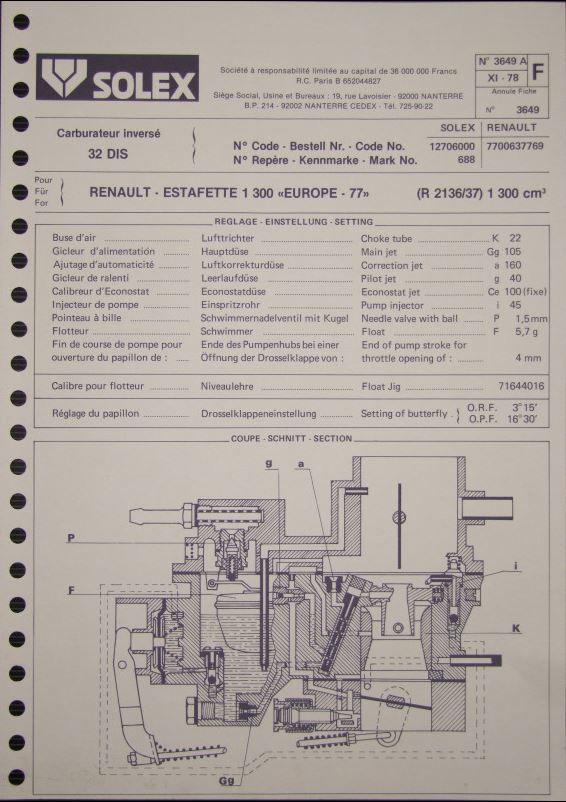

Estafette Solex PDIS / DIS

PDIS factory data from Estafette Manuals / FicheTechniques

| Model | Main | Air | Ratio | Pilot | Injector | Remarks |

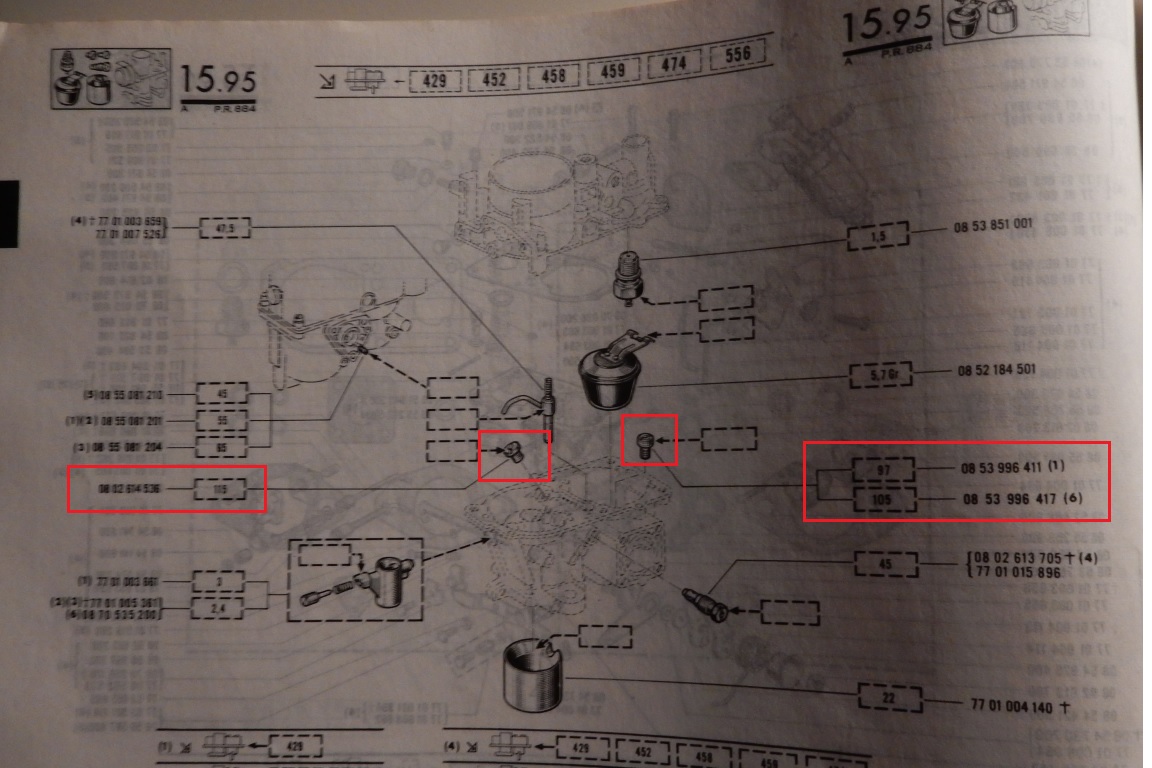

| R2136/2137 (1) | *97 | 115 | 1,19 | 45 | 45(55/65**) | PDIS, Manual PR884-4 |

| R2136/2137 (2)(3)(5) | 105 | 115 | 1,1 | 45 | 45(55/65**) | PDIS, Manual PR884-4 & fiche techniques |

| R2136/2137 (1) | *97 | 115 | 1,19 | 45 | 45(55/65**) | PDIS, Manual PR884-7 |

| R2136/2137 (6) | 105 | 115 | 1,1 | 45 | 45(55/65**) | PDIS, Manual PR884-7 & fiche techniques |

*A 97′ Main jet was used at the beginning (MR128)

**A 65′ injection jete was used in mountain models with height control (MR128)

o another carburetor type. Interesting are the different factory settings for the manual and automatic versions.

PR884-4 69-73 & PR884-7 69-76

PDIS factory data from the Solex datasheet (EUROPE-76)

Also look here www.plandegraissage.org

DIS factory data from the Solex datasheet (EUROPE-77)

Also look here www.plandegraissage.org

The air correction on the DIS carburetors is massively larger with jet 160 than on the PDIS (115)

Jets on my Solex Carburators

| Model | Main | Air | Ratio | Pilot | Injector | Remarks |

| R2136 / 1972 | 105 | 115 | 1,1 | PDIS | ||

| R2136 / 1972 | 105 | 115 | 1,1 | PDIS | ||

| ? | 105 | 160 | 1,52 | DIS, from Le Bon Coin | ||

| 2137 / 1970 | *107,5 | 160 | 1,49 | DIS (Replacement Carburator) | ||

| 2137 / 1978 | 105 | 160 | 1,52 | DIS |

I have not (yet) tested the PDIS with jet pair 105 / 115 with the AMM-L1 – but I would assume that the mixture is too fat in the upper turns. I cannot say how much the influence of the higher compression of the Couchette engine is.

Also I have not checked the jets of the enrichment system (Econostat) and the idle jet on any of the carburetors

Weber 32 DIR

The Fabbrica Italiana Carburatori Weber was founded in 1923 by Edoardo Weber in Bologna, Italy.

In 1952, Fiat acquired a little more than 50% of Weber’s shares in addition to its competitor Solex.

In 2001 they became part of the company Magneti Marelli Powertrain. In the 1990s, the production of carburetors was relocated to Spain. After a break in production, production has been resumed since the zero years.

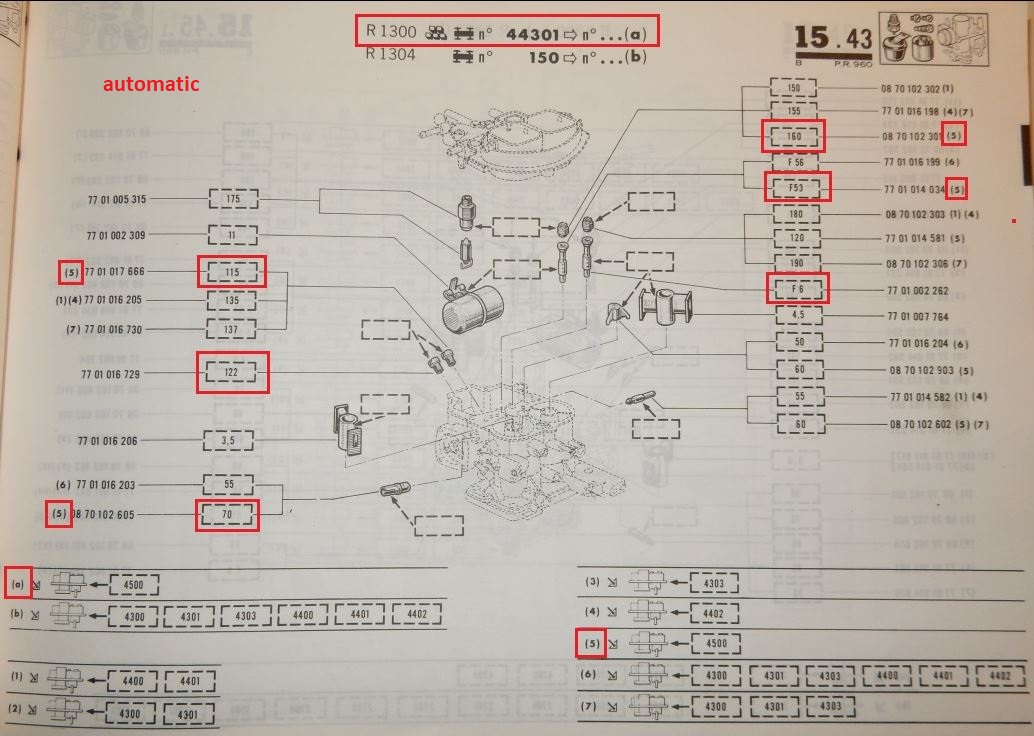

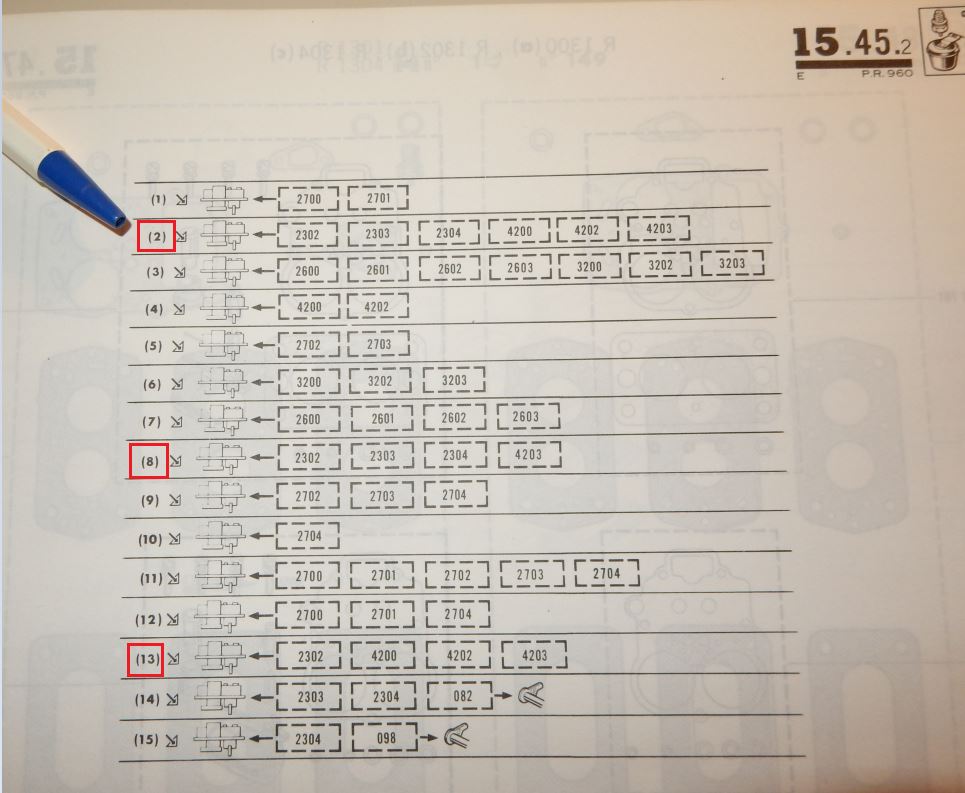

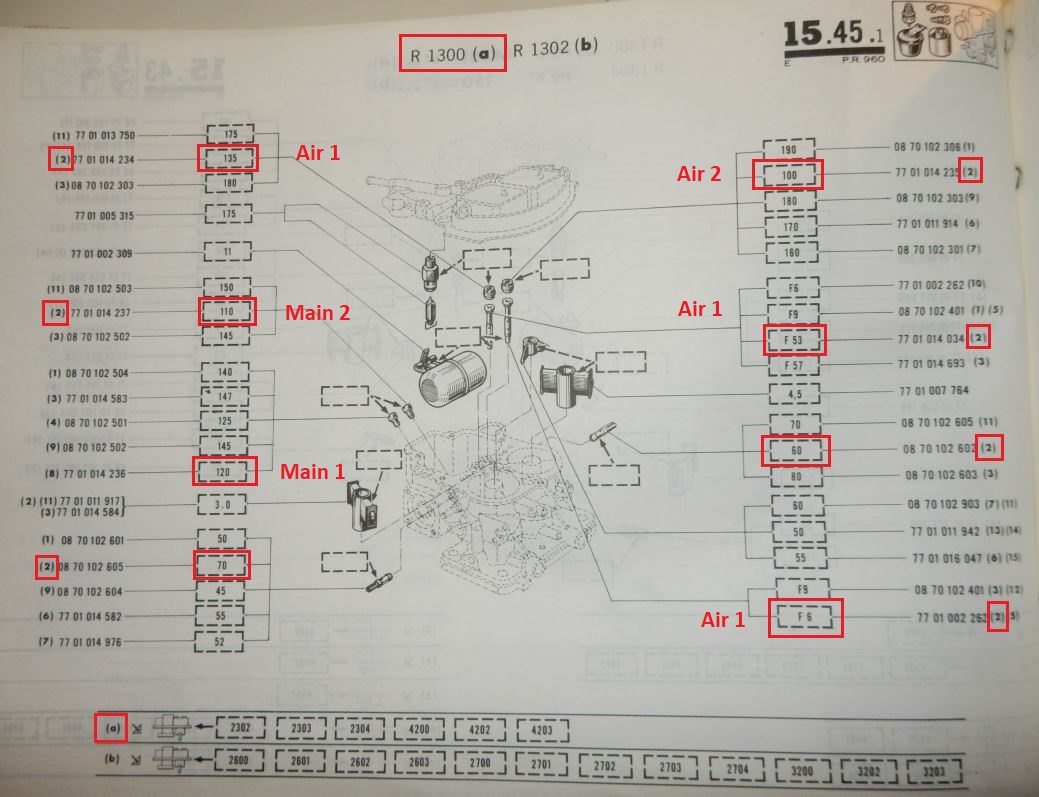

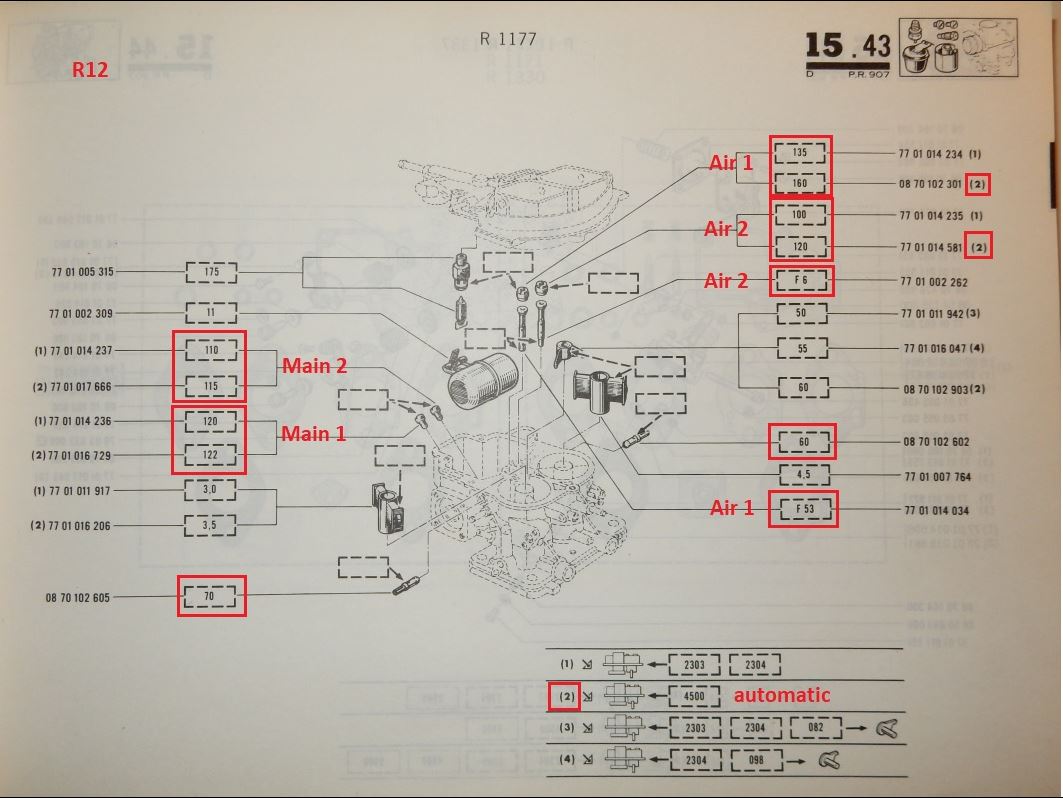

Factory data from the R15 and R12 manuals

| Model | Main 1 | Main 2 | Air 1 | Air 2 | Ratio 1 | Ratio 2 | Remarks |

| R12 (1) | 120 | 110 | 135 | 100 | 1,13 | 0,91 | Manual PR907 |

| R12 (2) automatic | 122 | 115 | 160 | 120 | 1,31 | 1,04 | Manual PR907 |

| R15TL (2) | 120 | 110 | 135 | 100 | 1,13 | 0,91 | Manual PR960 |

| R15TL (5) automatic | 122 | 115 | 160 | 120 | 1,31 | 1,04 | Manual PR960 |

Air correction jetholder (Emulsion Tube?)

Air Level 1; F53 (R15 = F53/F56)

Air Level 2: F6

Found on the Internet: Team R8 – jetting on a 32 DIR 21 from a R18 GTL 1. 4 liter

Jets on my 32 DIR 21 Carburators

The jettig complies with the manual

| Model | Main 1 | Main 2 | Air 1 | Air 2 | Ratio 1 | Ratio 2 | Remarks |

| R15TL | 120 | 110 | 135 | 100 | 1,13 | 0,91 | New Crankshaft Machine |

| R15TL | 120 | 110 | 135 | 100 | 1,13 | 0,91 | Old Crankshaft Machine |

Air correction jetholder comply also with the manual

Air Level 1; F53

Air Level 2: F6

The second air correction jet is very narrow (100 -> Ratio 2 = smaller 1)

This explains the behaviour in operation with the Lambda Regulation

With a good setting in the lower to middle range of rotation – to reach Lamda 1 I had to turn out the idle mix regulator screw 6-7 revolutions – the LED lights in the upper speed range continuously -> the 8mm diameter of of the control valve is not enough to regulate the mixture down to Lambda 1 in the upper speed range.

The base setting is much too fat in the upper area.

The only thing to say here is that with the Estafette the intake/air filter Ø is about 10-15 mm smaller – which may have an influence.

Tests / Test Setup

The following jets I bought

Main = 100 135 and

Air = 125 145 155 170

I did not check the jet of the enrichment system (Econostat) and the idle jet

A wide range of Weber spare parts is available at timms timms

……or also at carb.parts .

With them I have tested the following combinations

(bold = newly purchased jets):

| Model | Main 1 | Main 2 | Air 1 | Air 2 | Ratio 1 | Ratio 2 | Test |

| R15TL Variant 1 | 120 | 135 | 155 | 170 | 1.29 | 1.26 | 1 to lean 2 to fat More power |

| R15TL Variant 2 | 110 | 120 | 135 | 155 | 1.23 | 1.29 | 1 a bit to lean 2 to fat performance hole between 1 & 2 A bit more power & top speed |

| R15TL Variant 3 | 120 | 110 | 145 | 155 | 1.21 | 1.41 | 1 ok 2 a bit to fat at top speed Power & top speed same as original !!! BINGO |

| R15TL Variant 4 | 120 | 110 | 145 | 160 | 1.21 | 1.45 | not yet tested |

| R15TL Variant 5 | 120 | 120 | 145 | 175 | 1.21 | 1.46 | not yet tested |

With variant 3 the mixture at top speed is a bit too fat (from about 80-90% of the maximum speed) – which is probably not so bad:-)

Generally, during slow steady acceleration, the lambda regulation is also uniform

- during strong acceleration (full throtte), on the other hand, the LED is on for a longer time – even if the throttle is pushed through at low speeds.

- when you reach the speed and then take back the throttle, the LED starts to flash rhythmically.

- if you brake with the engine, the LED is completely off – logical, as the mixture leans because stationary gas ate high speed

Variant 4 with Air 2 = 160 or Variant 5 with Main 2 = 120 and Air 2 = 175 would have been interesting, but additional jets are needed.

In any case, this has to be adjusted again with the installation of a catalytic converter.

With the DIS one could try an air correction jet 140 to 155

Crankcase ventilation / secondary air

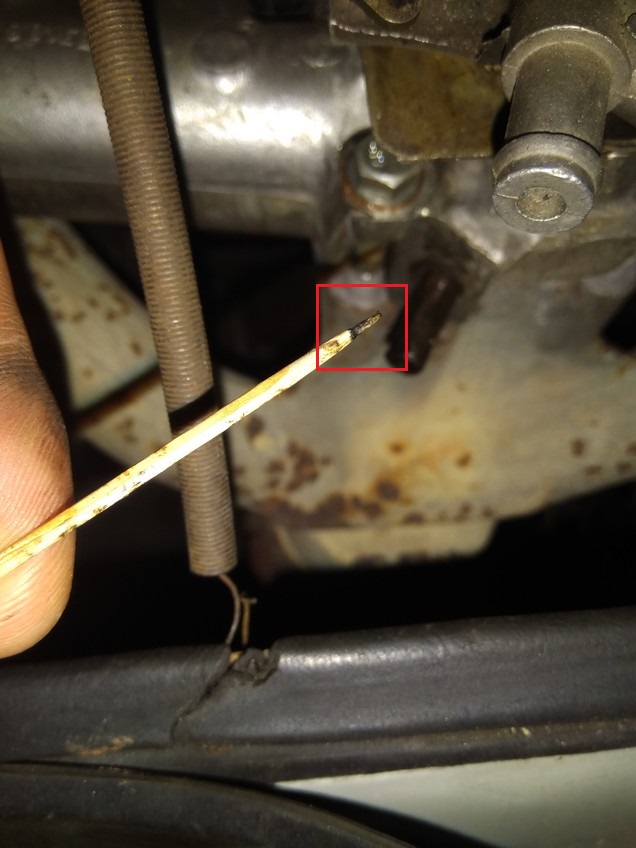

For the secondary air supply of the AMM-L1, I modified the existing connections for the crankcase venting.

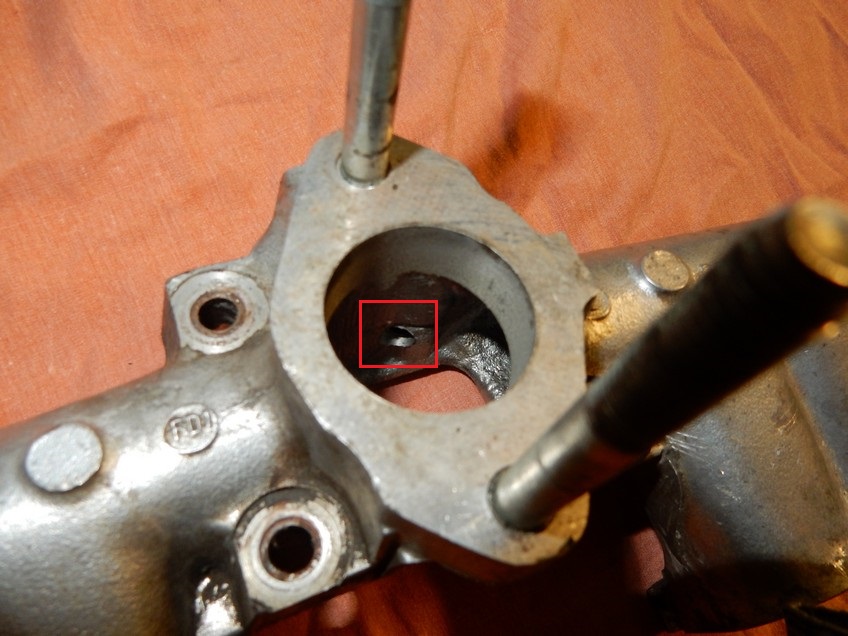

In the Estafette distributor I drilled out the cast steel tube and the aluminum “jet” (about 1.5 mm ) and glued in a new steel tube with Loctite

With the R15 and R12 the nozzle is inserted in the hose and the connecting tube has a continuous inner diameter of 6 mm.

Here I also drilled and welded a 90° connection angle tube with inner Ø 8mm and glued it with Loctite

The original aluminium cast-iron distributor of my couchette has no connection for the venting – the venting goes only to the carburettor, the two R2136 / 1972 and the R2137 / 1978 – have a “double venting” 1x to the carburettor & 1x to the distributor – here with a 1. 5 mm “jet”.

The Estafette distributor with the large bore is suitable for the AMM-L1

Finally a picture of the R15 distributor with original 6mm connector and with 8mm (here – for reasons of space – a 90° angle tube must be used!)

Resumée

The ratio of main nozzle to air correction jet of one carburetor type cannot probably not be simply transferred to another carburetor type – but at least it can give a clue. Interesting are the different factory settings for the manual and automatic versions.